Podium Deck Construction – A Complete Guide for Developers and Land Owners

Podium decks are changing how we build in cities. If you’re planning a multi-family, mixed-use, or urban infill project, you’ve likely heard the term. At JDJ Consulting Group, we help clients plan, permit, and manage projects like these across Southern California.

Table of Contents

ToggleThis guide explains podium deck construction in clear terms. We’ll walk through what it is, why it matters, and how to plan it well. From zoning laws to structural design, you’ll get a complete overview—plus insights from our team’s experience in the field.

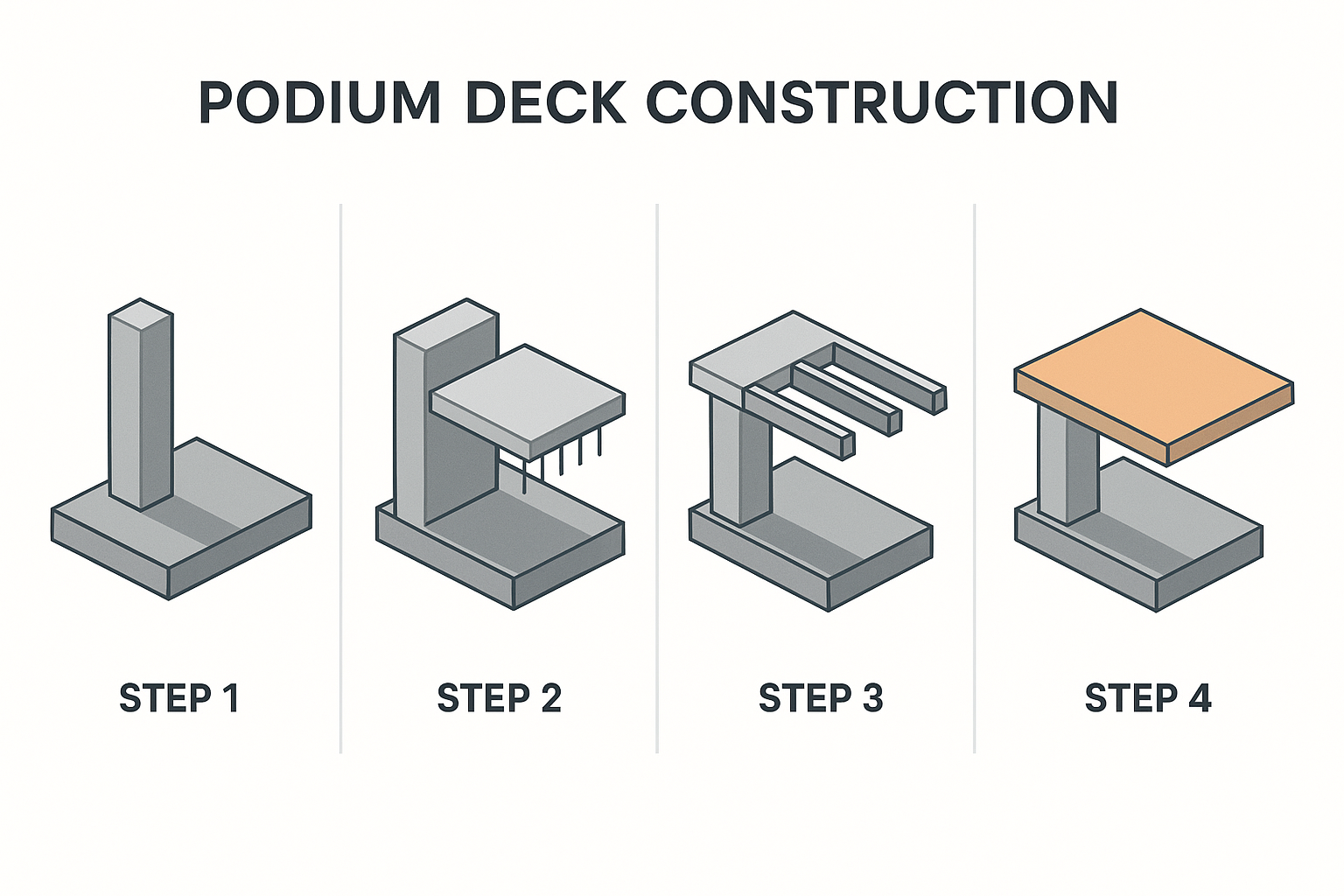

Podium Deck Construction Process

Step 1: Excavation and Footings

Excavate the area and install concrete footings.

Step 2: Podium Slab

Pour the podium slab on top of footings and columns.

Step 3: Columns Above Podium

Raise new columns for upper stories of the structure.

Step 4: Waterproofing and Finishes

Apply waterproofing membrane and finish the podium deck.

What Is a Podium Deck and Why Do Developers Use It?

A podium deck is a thick, flat concrete platform built at the ground level or just above. On top of it, developers can build several floors of wood-framed apartments, wooden structures, condos, or hotel rooms. This is known as podium construction or “wood over concrete.”

You’ll often hear terms like “5-over-1” or “4-over-1.” That means five stories of wood construction above one level of concrete. This concrete slab base usually holds parking, retail, or lobby space.

Why is this design so popular?

Because it lets you:

Build higher without exceeding local height limits

Use wood framing to lower costs

Add active ground-floor uses like retail or amenities

Meet strict fire codes with a concrete podium layer

Improve return on investment by increasing density

Comparison of Podium vs. Traditional Construction:

| Feature | Podium Construction | Traditional Slab-on-Grade |

|---|---|---|

| Lower floors | Concrete (Type I) | Wood or slab-on-grade |

| Upper floors | Wood framing (Type III or V) | Wood or light steel |

| Ground-level use | Parking, retail, lobbies | Living units or basic entry |

| Common building type | “4-over-1”, “5-over-1”, “2-over-3” | “3-over-0” or “2-over-0” |

| Fire separation required? | Yes (typically 3-hour rated slab) | No separation between levels |

| Where it’s used | Urban/mixed-use zones | Suburban or small-lot projects |

JDJ Tip: If your site is small but zoned for mixed-use or high density, podium decks help you get the most out of your lot.

How Podium Deck Construction Works in Simple Terms

Podium decks combine two construction types into one building. The base uses non-combustible concrete. Above that, the upper levels are built from wood. A fire-rated slab separates the two.

This setup satisfies strict fire and building codes while keeping project costs under control. The concrete podium acts as both structure and fire barrier. The wood above goes up faster and costs less than full concrete or steel.

What’s Inside a Podium Deck System?

| Component | Material | Purpose |

|---|---|---|

| Podium slab | Cast-in-place concrete | Main support deck, fire separation layer |

| Below deck | Parking, commercial space | Adds value at street level |

| Above deck | Wood-framed units | Apartments, condos, hotel rooms |

| Fire separation | 3-hour rated floor system | Meets IBC Section 510.2 code |

| Structural supports | Columns, shear walls | Handles vertical and lateral loads |

In places like Los Angeles, where zoning codes limit how tall a wood building can be, the podium structure makes room for more units without breaking the rules.

“5-over-1” and Other Common Podium Designs Explained

You might hear developers or architects use terms like:

“5-over-1” = Five wood-framed stories over one concrete base

“4-over-2” = Four wood-framed stories over two podium levels

These terms describe how many levels go above and below the concrete slab. Each configuration depends on zoning, site slope, and local height limits.

Key Terms and Code Rules to Know

IBC 510.2: Allows different construction types if separated by a fire-rated slab

Type I construction: Non-combustible materials like concrete and steel

Type III/V construction: Wood-framed with extra fireproofing

NFPA-13 sprinkler system: Required throughout podium and above

Seismic separation: Must handle movement between podium and upper floors

LADBS requirements: Extra steps in Los Angeles for inspections and approvals

JDJ Insight: If you’re unsure what your site allows, we offer early-stage feasibility reviews. These can save you months in redesigns and plan check delays.

Zoning, Planning, and Site Feasibility for Podium Deck Projects

Before any podium deck can break ground, you need to confirm whether your site allows it. That’s where zoning and feasibility come in. At JDJ Consulting Group, we help clients analyze land use potential before investing in full design work.

What to Look For First

Zoning code: Does it allow mixed-use, multi-family, or podium-height buildings?

Height limits: How tall can the total structure be—including the podium and rooftop elements?

FAR (Floor Area Ratio): Does the site allow you to build the square footage you need?

Setbacks: Are you limited in how close you can build to the property lines?

In Los Angeles and similar markets, even a small lot can support a high-density building—if it’s zoned correctly. JDJ helps clients interpret zoning maps, overlays (like TOC or CPIO), and Specific Plan rules that can affect what you can build.

Bonus: Use of SB 9 and SB 330 for Podium Housing

If your site qualifies, you may be able to streamline your approval timeline using California laws like SB 330 (for housing protection) or SB 9 (for duplex development). JDJ’s team stays on top of these changes and guides clients on how to apply them.

JDJ Tip: Always start with zoning before calling your architect. We can tell you what’s possible—and help you avoid redesigns later.

Coordinating Design Teams for a Podium Deck Project

A podium project requires multiple disciplines working in sync. You’ll need more than an architect—you’ll also need structural, civil, mechanical, and geotechnical teams onboard early. This collaboration avoids costly plan revisions and delays during city review.

Core Teams You’ll Need:

| Discipline | Key Responsibilities in Podium Projects |

|---|---|

| Architect | Overall layout, massing, floor plans, fire egress |

| Structural Engineer | Podium slab thickness, column layout, load calculations |

| Civil Engineer | Site grading, drainage systems, utilities |

| MEP Engineers | Mechanical, electrical, plumbing routing through podium levels |

| Geotechnical Engineer | Soil analysis, shoring requirements for underground parking |

| Permit Consultant | Coordinates submittals, corrections, LADBS requirements |

We recommend hosting a design kickoff meeting once zoning is confirmed. JDJ often facilitates this step, bringing all key players together to ensure the project is aligned with the city’s expectations.

JDJ Insight: Coordinated teams mean fewer plan check comments and faster RTI (Ready-To-Issue) status. That means platform construction can start sooner.

Understanding the Structural System of a Podium Deck

The structural design of podium decks can be complex. The lower podium acts like a “tabletop,” carrying the full weight of the wood-framed structure above. It also must absorb movement from wind, earthquakes, and ground conditions.

Podium Slab Options:

Cast-in-place concrete: Most common and versatile; allows easy customization

Precast planks: Faster to install but more rigid; harder to coordinate MEP layouts

Post-tensioned slab: Used when large spans or thinner decks are needed

Your structural engineer will decide which system fits your site, goals, and construction timeline. JDJ can work with your team to value-engineer a system that meets code without overspending.

Common Design Factors:

Live Load: Anticipates people, furniture, and vehicles on the deck

Dead Load: Weight of the structure itself

Shear Walls & Moment Frames: Resist lateral movement (especially in seismic zones)

Podium-to-Wood Interface: Must be flexible but structurally secure

JDJ Tip: Podium decks often create an “irregular structure,” which means special care must be taken with how loads are transferred. We help manage this during entitlement and plan check.

Waterproofing and Drainage: Why It’s Critical for Podium Decks

If there’s one part of podium construction that absolutely cannot fail—it’s the waterproofing. Because podium decks often have parking or living space below them, water intrusion can quickly become a disaster. At JDJ, we’ve seen small waterproofing mistakes lead to major repair costs or delays in Certificate of Occupancy.

🏗️ Podium Deck Construction Workflow

Layers in a Typical Podium Deck Waterproofing System:

Structural slab (usually cast-in-place concrete)

Waterproofing membrane (liquid-applied or sheet)

Protection board or mat

Drainage layer

Overburden (concrete topping, pavers, landscaping, or tile)

Every layer must be installed correctly. Any missed step could mean mold, ceiling damage, or liability issues for the property owner.

Common Drainage Solutions:

Scuppers and overflow drains on the perimeter

Slope-to-drain systems to move water away from living spaces

Waterstops at joints and penetrations (like plumbing or planters)

Expansion joints to allow for movement without cracking

JDJ Insight: Always bring in a third-party inspector for waterproofing. It’s not just about passing a checklist—it’s about protecting your long-term investment.

Long-Term Maintenance, Risks, and Warranties for Podium Structures

Once a podium deck is built, it’s not “set and forget.” Long-term durability depends on smart maintenance. This is especially true in cities like Los Angeles where temperature swings, seismic activity, and building movement are constant.

At JDJ, we guide clients on how to set up a maintenance program even before construction finishes. This includes documentation, inspection points, and warranty tracking.

Table: Risk Factors and How to Address Them

| Risk | What It Means | How to Prevent It |

|---|---|---|

| Water intrusion | Leaks from failed membrane or clogged drains | Pre-install testing + regular cleaning |

| Slab cracking or spalling | Cracks from movement or bad curing | Control joints + proper concrete mix |

| Drainage system failure | Pooling water or backups on deck surfaces | Regular scupper cleaning + visual inspections |

| Plant roots damaging membrane | Landscape roots break into waterproofing layer | Root barrier + proper planter design |

| Maintenance access blocked | Overbuilt decks hide drain lines or test points | Include maintenance paths in original design |

Key Warranty Notes:

Many membranes come with 10-year material warranties, but only if installed by certified pros

Third-party inspection reports are often required to activate the warranty

Developers should document every repair, patch, or leak test to maintain compliance

JDJ Tip: Don’t skip post-construction manuals. Make sure your property manager knows how to inspect the deck quarterly. We provide handoff packages to make this easy.

Sustainability and Cost Benefits of Podium Deck Construction

Podium decks do more than maximize space—they also support cost and environmental savings over the life of a building. That’s why they’ve become a go-to strategy in cities looking to expand affordable housing, reduce emissions, and support mixed-use growth.

Benefits You Can Count On:

Lower embodied carbon from using wood framing above the podium

Faster construction timelines thanks to modular wood systems

Less need for underground parking, reducing excavation and soil hauling

Design flexibility for future solar, green roof, or amenity installations

Where the Savings Show Up

| Construction Area | How Podium Decks Reduce Cost |

|---|---|

| Structural framing | Wood above deck is faster and cheaper than concrete |

| Foundation | Less excavation than full subterranean parking |

| Fireproofing | Concrete podium handles key fire code requirements |

| Timeline | Faster build = reduced carry cost |

| Financing | Allows higher density on smaller parcels |

JDJ Insight: With the right layout, podium decks can cut both soft and hard costs. We work with developers early to identify these savings before plans are finalized.

How JDJ Consulting Group Supports Podium Deck Projects From Start to Finish

Podium construction can unlock incredible value on the right site—but it also comes with layers of complexity. At JDJ Consulting Group, we guide property owners, developers, and architects through every step. From early-stage zoning studies to RTI (Ready-To-Issue) permits, our job is to prevent costly mistakes and accelerate timelines.

Services We Provide for Podium Projects:

Zoning & land use analysis

We help you determine if a podium deck is feasible based on lot size, zoning code, and local overlays (like TOC or Specific Plans in LA).Pre-construction feasibility studies

Before you hire a full design team, we offer high-level cost projections, density studies, and yield models.Permit processing and RTI support

Our team manages plan submittals, city agency coordination, and correction cycles until your project is ready to build.Project management and value engineering

We help reduce unnecessary scope and make smarter material or structural choices based on local conditions and code limits.

Example: JDJ’s Role in a 5-Over-1 Mixed-Use Project

On a recent 5-over-1 project in West LA, our team:

Identified unused density bonuses through TOC

Helped redesign the podium deck to reduce excavation costs by 20%

Resolved LADBS correction items in 30 days, cutting 2 months off the RTI timeline

Provided contractor-ready estimates that helped the owner secure funding faster

JDJ Tip: If your project is stuck in the plan check process, we can step in and get it moving again. Our team is deeply familiar with LADBS and local approval cycles.

📊 Podium Configurations by Region

Frequently Asked Questions About Podium Deck Construction

What key advantages does Podium Construction offer?

Podium construction helps save money and time while offering design flexibility. It uses a strong base (usually concrete or steel) for retail or parking, and lighter wood for the upper floors. This method is fast, safe, and great for mixed-use projects.

Main benefits include:

Fast setup with panelized wall systems

Energy savings from smart building design

Lower cost for residential floors

Supports stores, restaurants, or garages below

Builds taller while meeting code limits

What is Podium Construction?

Podium construction is a building style with two parts: a strong base and lighter top floors. The bottom is often made of concrete or steel and supports retail or parking. Above it, four to five stories of wood framing hold apartments or offices.

Typical features:

1–2 levels of concrete or steel podium

4–5 levels of wood frame construction

Used in urban, mixed-use, and housing projects

Saves costs while meeting fire code rules

Sources:

What exactly is Podium Construction?

Podium construction, also called pedestal construction, separates a building into two zones. A concrete or steel “podium” forms the base. Above it are wood-framed residential floors. This design supports both function and safety.

You’ll often find:

Lower podium for shops, parking, or offices

Wood-framed housing above

Clear fire-rated divide between levels

Cost-effective design in dense areas

Is Podium Construction Sustainable?

Yes, podium construction is eco-friendly, especially when the upper floors use wood. Wood is renewable and stores carbon, making it a green choice. The strong podium below adds safety and energy control.

Green benefits include:

Engineered wood reduces emissions

Concrete podium improves energy use

Lighter material needs fewer resources

Meets green codes and LEED targets

Source:

What are the varieties of Podium Construction?

Podium buildings fall under two types: Type III and Type V. Each has different fire rules and material limits.

Quick breakdown:

Type III: Wood inside, fire-rated walls outside

Type V: All wood, less fire-resistance, lower cost

Type III allows taller buildings

Both work for mixed-use and housing

Can you build multiple podium levels?

Yes, you can build more than one podium level, but it depends on the site and code. A common example is a “2-over-5” layout—two levels of concrete podium beneath five stories of wood framing. This setup works if the project meets local height limits, structural capacity, and fire code rules.

Key factors to consider:

Site zoning and max building height

Structural load capacity of lower podiums

Compliance with fire safety and egress codes

What’s the biggest risk in podium construction?

The biggest risk is water intrusion. Since podium decks act as a barrier between the upper floors and below-grade areas, even a small leak can lead to serious damage. Parking levels, storage, and utility systems are often below the podium—making waterproofing solutions critical.

Risks from poor waterproofing:

Mold and material rot in hidden areas

Damage to electrical and mechanical systems

Costly repairs or code violations later on

How early should you bring in a permit consultant?

As early as possible—ideally before design is finalized. Permit consultants help navigate zoning rules, height limits, parking ratios, and entitlement options. If they come in too late, you may miss chances to optimize the layout or speed up approvals.

Why early input matters:

Avoids redesigns caused by code issues

Speeds up plan checks and approvals

Helps maximize building size and use

🧠 Test Your Podium Deck Knowledge

1. What is a common fire separation requirement between podium and wood-framed levels?

2. Which of these is not typically below a podium deck?

3. What type of consultant helps push plans to RTI?

Ready to Launch Your Podium Deck Project?

Talk to our land use consultants and get expert help on zoning, permitting, and project planning—right from day one.

Schedule a Free ConsultationDo all podium decks require a fire separation?

Yes. All podium decks need a fire-rated separation from the levels above. Building codes (like IBC 510.2) require a 3-hour fire-rated slab between the podium and any wood-framed floors. This ensures that fire won’t spread easily from commercial or parking areas to residential units.

Fire separation requirements:

3-hour horizontal fire barrier

Must separate different construction types

Required in all mixed-use podium designs

What cities allow podium construction?

Many major cities allow podium construction, especially in dense urban areas. In California, cities like Los Angeles, Glendale, Long Beach, and Pasadena support podium designs for residential and mixed-use projects. These cities promote podium layouts to meet housing demand while managing land use.

JDJ Bonus Insight:

We track zoning trends in each city. Our permit consultants use local checklists and plan reviewer preferences to help you avoid common delays.

Final Thoughts: Why Podium Decks Matter and How JDJ Can Help

Podium decks offer an efficient, code-compliant way to build taller, denser, and more flexible buildings. When planned correctly, they support affordable housing, activate ground-floor retail, and open up valuable parking or utility space—without digging deep into the ground.

But podium projects also require the right strategy, team, and timing. That’s where JDJ Consulting Group comes in. We bridge the gap between planning and execution—making sure your project moves forward with fewer surprises and better outcomes.

Let’s Get Your Podium Project Moving

Ready to explore podium deck construction for your next project? Contact JDJ Consulting Group for:

Feasibility and zoning analysis

RTI support and permit processing

Project management and value engineering

We’re here to help you build smarter—from the ground up. Schedule your free consultation today. Call us at (818) 233-0750 to get started right away!